| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | YH |

| Certification : | ISO9001 |

| Price : | $10000-$35000/set |

| Payment Terms : | T/T |

| Supply Ability : | 60 Sets/month |

| Delivery Time : | 50-75days |

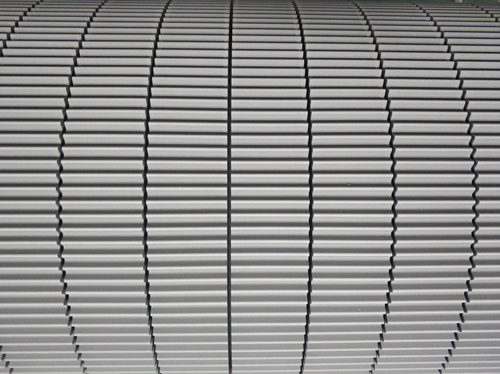

B Flute Corrugation Machine Parts Tungsten Carbide Corrugating Rolls

| Product name | Corrugating rolls, corrugated roller |

| Material | 50CrMo |

| Application | Single facer, corrugator machine |

| Diameter | 200-600mm |

| Width | 1000-2800mm |

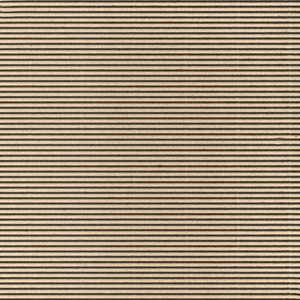

| Flute Profile | A, C, B, E, F, G, N, O |

| Heating Treatment | Intermediate frequency quenching treatment |

| Hardness | ≥HRC58 after heating treatment, harden layer 8-12mm |

| Coating | Tungsten carbide, hard chrome 0.06-0.08mm |

| Corrugator line | BHS, Fosber, BW Paper System, Hsieh Hsu, K&H, JS, Fuli, Wanlian, Taiwan Mingwei, Chinese Mingwei, Meiguang, Dongguang, Dpack, Xinguang, Xieyang, Shengli, Indian machine, etc. |

Advantages

☆ The domestic first-class technology and core operating team, each member has rich experience with processing more than 5000 sets of corrugated roller. Depending on the mature stable Taiwan craft technology and the advanced international technology, we offer the optimized design of corrugating roll flute profile totally according to costumer’s requirement.

☆ The CNC intermediate frequency heat treatment quenching machine adopts the foreign corrugating roll quenching technology and makes the hardness of the substrate reach more than HRC58 degrees, meanwhile it retains the toughness and maximizes the anti-thermal deformation of substrate to ensure the stability of corrugating rolls.

☆ The leading domestic high precision and high performance CNC corrugating roll precision grinders, lathe, planer, and other equipment are equipped with Germany's Siemens control system, increase grinding accuracy in the maximum.

☆ With the mature of tungsten carbide plating technology, the most advanced tungsten carbide coating equipment Praxair JP8000 , as well as high quality imported Praxair tungsten carbide powder, the abrasion performance of corrugating roll is extreme and maximize the extension of the service life of the corrugating roll.

Precision Welding Can Be Inseparable

Both ends of the roller body should be heated to release the size of the inner bored hole. After the spindle heads are put in, the roller body and the spindle heads should be held tightly after natural cooling. When everything is ready, a driving fit interface has been formed between the roller body and the spindle heads by means of preheating, welding or bolting. Special care should be taken when welding, because finished corrugated roller body’s temperature will rise constantly when the roller is running, and the roller body also bears pressure of the steam from the inside of the roller body, which will form the so-called “pressure vessel”. In view of this, the roller body and the spindle heads joint must pass the pressure test. When the welding process finished, the work piece shall be put into the furnace for high temperature tempering to reduce stress.

Heat well for faster speed and better cardboard

A. Start the corrugating rolls before filling in steam to avoid abnormal deformation.

B. Check the temperature of corrugating roll and pressure roll regularly to avoid temperature decrease caused by accumulation of condensate water.

If the temperature is abnormal, please check and keep the correct position of siphon to let condensate water out successfully.

|