| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | YH |

| Model Number : | 1850mm×320mm |

| Price : | $5000-$15000/set |

| Payment Terms : | T/T |

| Supply Ability : | 1500 sets per year |

| Delivery Time : | 60-90 days |

| Certification : | ISO9001 |

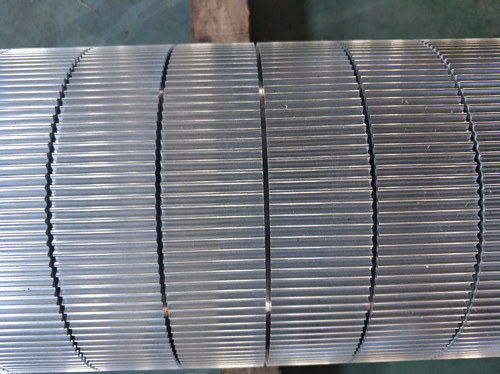

C Flute Hard Chrome Plated Corrugated Roller for Corrugator Machine

| Product name | Corrugating rolls, corrugated roller |

| Material | 50CrMo |

| Application | Single facer, corrugator machine |

| Diameter | 200-600mm |

| Width | 1000-2800mm |

| Flute Profile | A, C, B, E, F, G, N, O |

| Heating Treatment | Intermediate frequency quenching treatment |

| Hardness | ≥HRC58 after heating treatment, harden layer 8-12mm |

| Coating | Tungsten carbide, hard chrome 0.06-0.08mm |

| Corrugator line | BHS, Fosber, BW Paper System, Hsieh Hsu, K&H, JS, Fuli, Wanlian, Taiwan Mingwei, Chinese Mingwei, Meiguang, Dongguang, Dpack, Xinguang, Xieyang, Shengli, Indian machine, etc. |

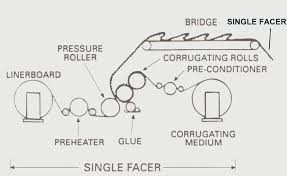

Applications:

Corrugating roll is one of the most important components in corrugated carton production. Usually, it is an essential part of single facer. Corrugating rolls consist of two parts: upper roll and lower roll. The lower corrugating roll is the driving roll, which is generally fixed while the upper one is the driven roll.

How to adjust the hard chrome plated corrugated rollers well?

1. Inspect the balance of corrugating roll regularly, at least once a month.

2. Inspect the gap among corrugating roll, glue roll and pressure roll to avoid abrasion.

3. When installing corrugating rolls, mind the small gap between corrugating rolls and suction hood which will cause abrasion of corrugating rolls and aluminum plate from suction hood.

4. The copper knives will loosen with the movement of machine. The knife in “T” position will scratch the coating on two sides of grooves. So fix the cooper knives regularly.

5. In the premise of assuring corrugated board quality in real production, it’s better to use smallest oil/air cylinder pressure both of corrugating roll and pressure roll.

6. When changing wide width to small width in real production, reduce oil/air cylinder pressure both of corrugating roll and pressure roll accordingly to avoid abnormal abrasion caused by excessive pressure. Especially the direct abrasion between corrugating rolls and pressure roll in paperless areas will cause falling off of coatings.

Production Process of Chrome Plated Corrugated Roller:

Lathing ⇒ Welding⇒Heating Treatment ⇒Cylindrical Grinding⇒ Engraving⇒Chrome Coating ⇒Testing⇒Packaging

|